Conductor concepts for the internal oxidation of Nb3Sn-based superconductors

Applications in high-energy physics such as the Future Circular Collider (FCC) at CERN require a performance increase of about 30 % to 50 % of the of superconducting wires using state-of-the-art technology. The superconducting material in these wires is Nb3Sn, a brittle intermetallic material that forms during a final heat treatment after the wire has been wound into its desired shape. A promising method to improve the performance of such a wire is the creation of artificial pinning centers in the form of oxide precipitates. These nanoscale, non-conducting particles improve the superconducting material in two ways: First, the particles themselves can retain the magnetic field that penetrates the superconducting wire. Secondly, the particles can lead to grain refinement in the Nb3Sn formed. Since grain boundaries act as pinning centres in Nb3Sn, the refinement of the grain structure also leads to more pinning centres. The generation of pinning centers, either in the form of precipitates or as grain boundaries, improves the current carrying capability of the superconducting material. However, the required non-conductive particles cannot be incorporated directly into the precursor materials of the wire, as they would lead to excessive work hardening and ultimately to strand breakage during manufacture. Instead, the heat treatment must produce precipitates in addition to Nb3Sn. For this purpose, a less noble alloying element to be oxidized is incorporated into the Nb alloy precursor, from which Nb3Sn is finally formed. In addition, an oxygen source is introduced into the conductor. During heat treatment, oxygen diffuses from the oxygen source into the Nb alloy precursor and oxidizes the alloy element. In this way, work hardening and possible failure of the wire is avoided, as the nanoscale precipitates are only produced after the wire has been brought into its final shape.

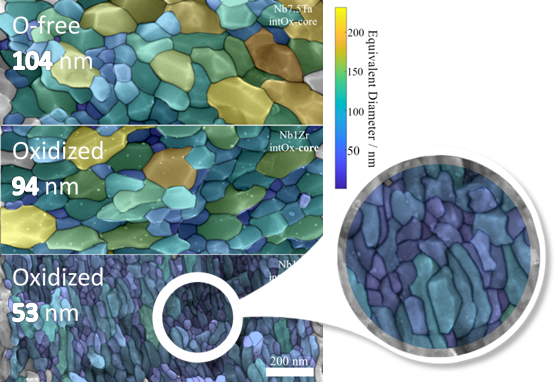

As part of a larger collaboration with CERN, Bruker EAS GmbH and ITEP at KIT are collaborating in the development, production and analysis of conductors designed for such internal oxidation of the Nb alloy. It could be shown that artificial pinning centers can be created in the formed Nb3Sn and that the time of precipitation formation strongly influences the morphology of the formed Nb3Sn. The precipitates were observed to actually act as artificial pinning centers that improve the conductor's performance - especially at high fields. By choosing a suitable conductor design, it was possible to generate precipitates and further refine the Nb3Sn grain size (see figure).

- C. Buehler, B. Sailer, M. Wanior, V. Abaecherli, M. Thoener, K. Schlenga, S. Kauffmann-Weiss, J. Hänisch, M. Heilmaier, B. Holzapfel, Challenges and Perspectives of the Phase Formation of Internally Oxidized PIT-Type Nb3Sn Conductors, IEEE Trans. Applied. Supercond. 30, 6000805 (2020), DOI: 10.1109/TASC.2020.2969906