Structural and Functional Materials for Cryogenic Application

Material research for cryogenic applications have been carried out at the KIT Institute for Technical Physics (ITEP) within the framework of various research projects for more than 30 years. These include superconducting magnet technology, cryogenic energy applications for superconducting motors, generators, and transformers as well as topics in aerospace and medical technology.

Material Development Within this research topic, materials (metal alloys or fibre composites) are defined and analyses are performed on manufactured test specimens, for example from melts or additive manufactured material samples, under operationally relevant conditions.

Material Qualification Based on standardized test methods, adapted test conditions are created in order to match the extraordinary requirements of material characterization and analysis of the very different R&D work or, if necessary, to develop new ones. In order to characterize the produced materials as comprehensively as possible, the following measuring methods at cryogenic temperatures (RT-4.2K) are mainly used:

- - mechanical axial/torsional/bending/shearing behaviour under static or alternating load, fracture behaviour

- - physical quantities such as electrical/thermal conductivity, therm. expansion, heat capacity, magnetisation

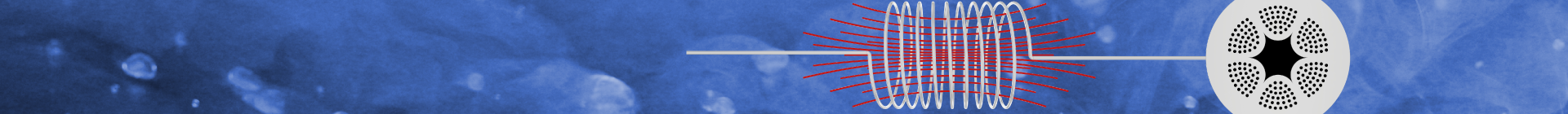

- - electro-mechanical behaviour of single or stranded superconducting tapes

- - microstructural investigations for material and failure analysis

The tasks range from basic material developments and investigations to R&D projects together with industry and standardisation work, for example in the DKE/IEC. The results of the research work flow directly into publications and teaching.

Research infrastructure: CryoMaK FuSyC HV Laboratory Cryogenics