DIPAK

The new DIPAK facility to be built (commissioning planned for 2026) stands for Direct Internal Recycling Development Platform Karlsruhe and describes the combination of different research infrastructures in one building. These are

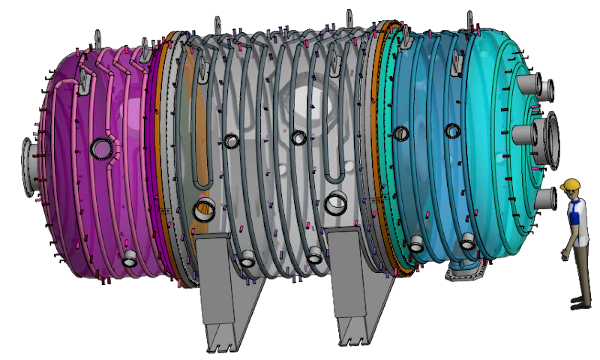

- a test facility for all relevant vacuum technologies with a 28 t, 7x3.5 meter vacuum test vessel, which replicates the torus or pump duct of a fusion reactor,

- a mercury laboratory including a purification plant for waste water and contaminated mercury,

- a laboratory for research of superpermeability and hydrogen isotope separation processes,

- a pellet laboratory for the production of frozen hydrogen pellets,

- a computer cluster for particle simulations and the dynamic simulation of the fuel cycle and

- all infrastructure necessary to process mercury and hydrogen safely and reliably.

DIPAK also allows the testing and qualification of equipment for DEMO on a prototype or even 1:1 scale, making DIPAK a key facility for a future demonstration power plant.

The DIPAK vacuum test vessel is the heart of the development platform and allows the performance of numerous experiments up to the testing of DEMO equipment in 1:1 scale.

DIPAK should become available around the middle of the 9th Framework Programme (from approx. 2026), in time to test previously developed equipment for the DEMO Fuel Cycle (e.g. vacuum pumps) and to validate design codes.

The results will then form the basis for the DEMO Engineering Design Phase, which is scheduled to start in 2028.