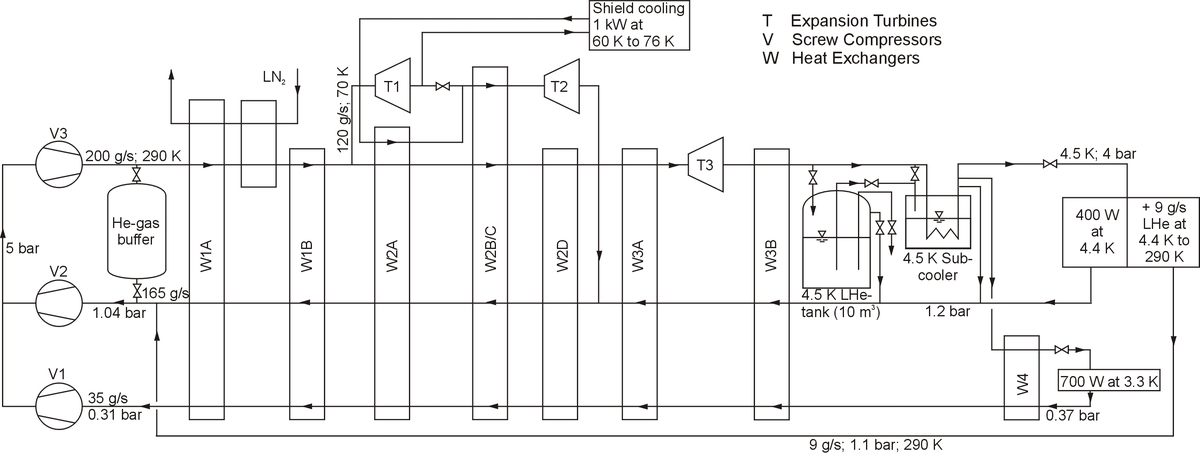

The cooling process of the 2kW system is based on the Claude principle. The compressed helium gas flow is split after the first heat exchanger at 80K. Part of the helium flows through two dynamically gas-bearing turbines and cools down to around 11K due to the adiabatic expansion. This gas flow is then returned to the suction side of the compressor and cools the main gas flow with the help of plate heat exchangers. After cooling to about 11K, the main gas flow is expanded to 4bar using a Joule-Thompson turbine and thereby further cooled down to 4.5K.

The 2kW system can be operated in ten fully automatic modes. The modes of operation include cooling at 3.3K, cooling at 4.4K, liquefaction and various combinations.

.Technical details:

• Manufacturer - Linde AG

• Cooling capacity - 2kW at 4.4K (e.g. 700W at 3.3K, 400W at 4.4K and 1kW at 70K) or 21g / s condensation

• Connected load - 460kW (partial load) to 880kW (700W-3.3K + 400W-4.4K + 1kW-70K, without JT turbine)

• Compressors - 3 Aerzen screw compressors

• Vacuum compressor - throughput 34.5g / s, suction pressure 260mbar, final pressure 5.5bar

• Normal pressure compressor - throughput 188g / s, suction pressure 1bar, final pressure 5.5bar

• Final stage compressor - throughput 213g / s, suction pressure 5.5bar, final pressure 17.8bar

• Storage capacity for liquid helium - 10,000 liters