Materialography

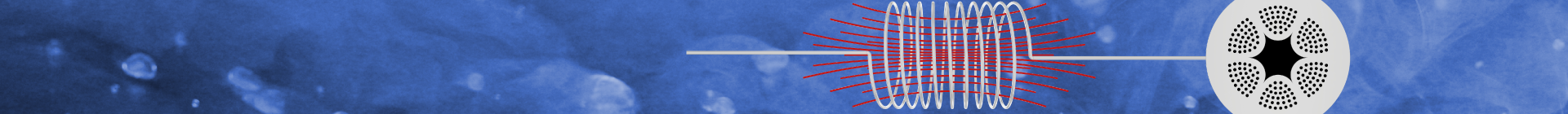

In the materialographic laboratory, all preparative methods are available to prepare all samples produced at the ITEP for microscopic examination of the structure and microstructure. The range of samples/questions ranges from the structure of superconducting cables and coated conductors and their integration into power engineering components to the characterization of thin films (PLD or CSD) and the structural analysis of deformed metals.

In detail we have the following preparative possibilities:

- Precision cut-off machine Secotom-50 (Struers) for the sampling of smaller and larger components. The maximum sample size is 190/258/203 mm (L/W/H). Cut-off wheels are available in aluminium oxide and silicon carbide.

- Diamond wire saw Well 4240 for precise cutting of samples with a 0.3 mm diamond wire.

- Ion surface and cross section polishing system IB-19500CP Cross Section Polisher (Jeol) with ion acceleration voltages from 2 to 8 kV. The maximum sample size is 10/11/2 mm (L/W/H).

- Cold embedding of samples (Struers) also in individually adapted shapes.

- Hot embedding of the samples with Prontopress (Struers) at 180 °C and 30 kN results in round samples of 40 mm diameter.

- Grinding and polishing machine TegraPol-35 with TegraForce-5 and TegraDoser (Struers) including 6-fold specimen holder with single and central pressure.

- Vibration polishing unit VibroMet-2 (Buehler) for final polishing of the samples.