Electromechanical testing of HTS fusion conductor samples at 4.2K and B <= 12T

-

Author:

Daniel Nickel

Abstract

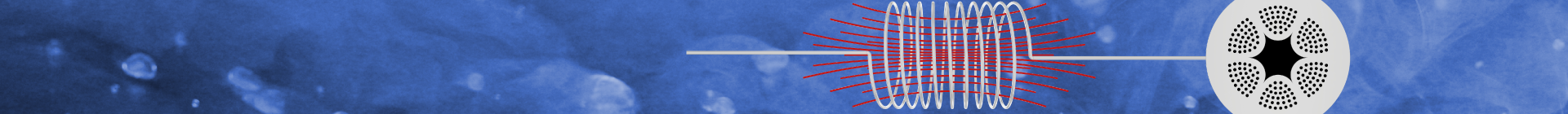

High temperature superconductors (HTS) offer the possibility to increase temperature safety margins and the maximum magnetic field strength in fusion magnet systems. Currently HTS are discussed to be used in EU-DEMO in the innermost layers of the Central Solenoid [1]. HTS based cable designs are mostly composed of few macro-strands,

which themselves are fabricated from assemblies of flat coated conductor REBCO HTS tapes. The HTS CrossConductor is a HTS macro-strand, in which HTS tapes with two different widths are combined in a cross shaped stack to maximize the HTS density in a round outer shape.

Within an international collaboration on the quench performance of cabled sub-scale HTS cable-in-conduit-conductors, a design based on a triplet of HTS CrossConductors was developed [1]-[3] and a sample was tested at 4.2 K and fields up to 12 Tesla [3].

In this work, two samples with sample layout similar to [3] were prepared and tested under tensile stress to simulate hoop stress of coil windings in a fusion environment. The two samples differ in the superconductor distribution within the sample, to investigate the overall performance of this conductor layout and the behavior of a single strand inside the conductor.

Experiments were carried out at 4.2 K in a liquid helium bath with currents up to 10 kA in the FBI test facility at forces up to 100 kN and an external magnetic field up to 12 Tesla. Results are compared with experimental [4] and modeling analyses on different cabled HTS CroCo-based triplet designs [2], [4].