Coil and Magnet Technology

In the research area Coil and Magnet Technology concepts and technologies are developed for the production of complex and specific coils for various applications in spectroscopy, medical technology, high energy physics, fusion, high field technology, industrial plants and electrical power engineering. Research is focused in particular in the following areas:

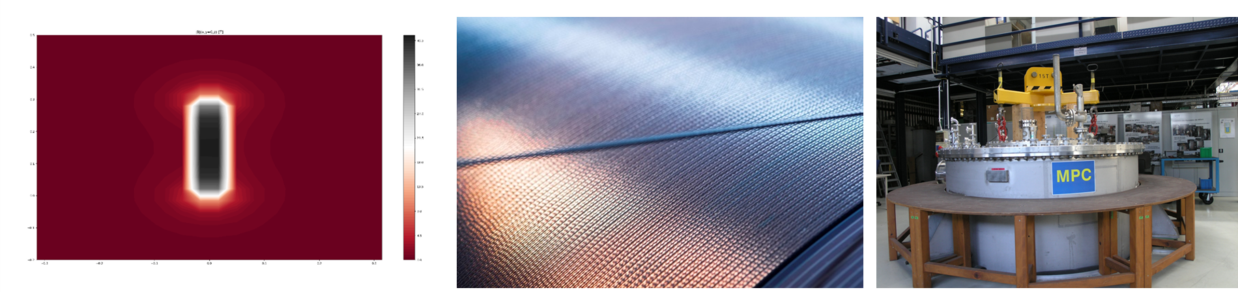

Coil design: To utilize the technical superconductors to the highest degree, wire properties and design of the windings have to be aligned. This includes the electromagnetic design, the mechanical design, operational requirements, etc. and the appropriate cooling approach.

Winding preparation: The dedicated winding system is constructed out of the suitable winding system. For this purpose, a technical winding workshop with various machines is available. Robotic winding technology has been under study, development and in realization since 2020. This also enables the construction of complex 3D geometries (e.g. saddle coils or for Fusion) that go beyond simple solenoids, planar pancake or racetrack coils.

Impregnation: The windings must be embedded in a suitable material depending on the application. Aspects such as operating conditions (temperature, mechanical and electrical stresses, heat dissipation, etc.) must be taken into account in the choice of material, process, etc. A laboratory VPI-apparatus with a large vacuum chamber is under construction and expected to be operational by late 2020.

Characterization: For the characterization of technical superconductors and components thereof (e.g. windings and coils), the magnet laboratory has a wide variety of cryostats and outsert magnets (up to a maximum of 26 T) at its disposal. A large cryostat (usable diameter maximum 1190 mm, maximum length 1848 mm) with cryocooling (approx. 10 K to 300 K) is presently in the refurbishment and instrumentation stage.