Energy storage systems and multimodal components

60kW Flywheel Energy Storage System

A flywheel is a storage technology that contains energy in kinetic form. This energy is quadratically proportional to the rotor speed. In order to increase the stored energy, technologies for increasing the speed are therefore being investigated.

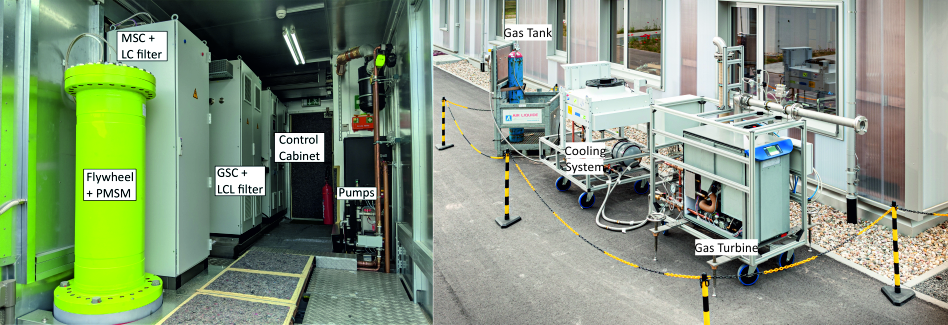

The 60kW flywheel system at the PHIL laboratory consists of:

The actual flywheel rotor, which is made of carbon fiber reinforced plastic and rotates magnetically mounted in a vacuum housing at a maximum speed of 45000 rpm.

The electrical machine (in our case a permanent magnet excited synchronous machine), which either converts the mechanical energy from the rotor into electrical energy (the system discharges) or electrical energy into rotational energy (the system charges).

The power electronic converter, which connects the electric machine to the mains and controls the speed of the rotor.

The electronic controller, which ensures the safe operation of the machine.

Micro gas turbine

Power to Gas" is seen as an important key technology for achieving the goals of energy system transformation. With this technology, electricity is electrochemically converted into gas and stored, transported and made available again in existing gas infrastructures. Research is being conducted on many links in the conversion and distribution process.

Our network of plants examines in detail the last link in this chain, the process of converting gas into electrical and thermal power at the end consumer. The work includes modelling, the development of application scenarios and the experimental investigation of the behaviour of the gas turbine in the application case.

The unique selling point of this project is the integration of all work steps into the so-called real-time simulation environment (Power Hardware in the Loop). In contrast to theoretical simulations, the existing real-time simulation system enables us to connect the real gas turbine and the simulation model. This means that all investigation and modelling results can be scientifically validated reliably. This benefits above all the results of the application scenarios and, as a result, their informative value.

Data sheet of the plant:

- Electrical power: 3.2 kVA

- Thermal output: 15.6 kW

- Turbine speed: 240,000 rpm

- Fuel: methane

- Manufacturer: MTT Micro Turbine Technology